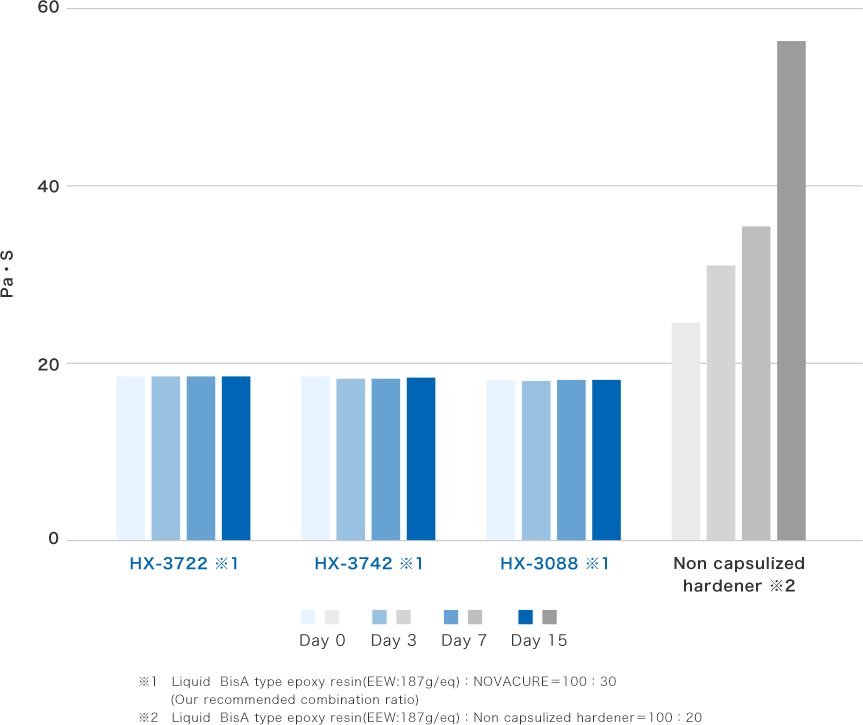

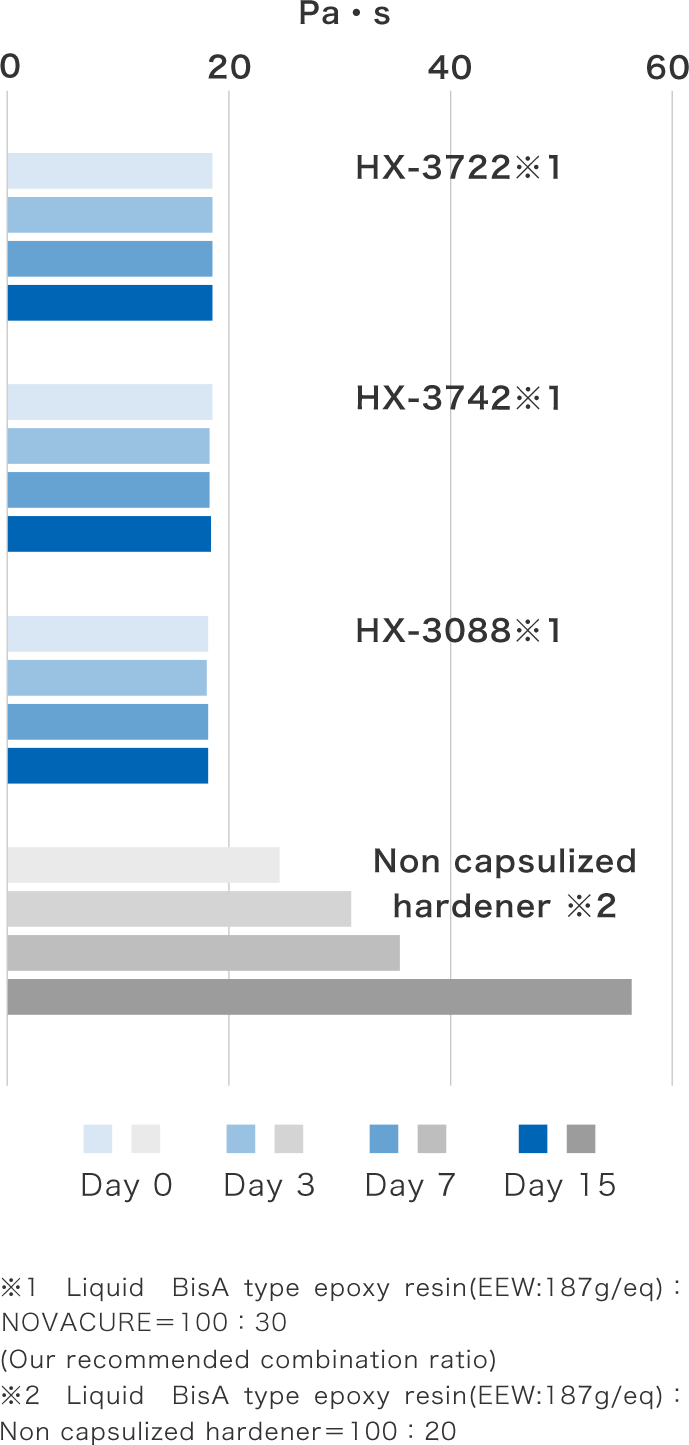

| initial | Day 3 | Day 7 | Day 15 | ||

|---|---|---|---|---|---|

| HX-3722 ※1 | 30phr | 18.4 | 18.5 | 18.5 | 18.5 |

| HX-3742 ※1 | 30phr | 18.4 | 18.2 | 18.2 | 18.3 |

| HX-3088 ※1 | 30phr | 18.1 | 18.0 | 18.1 | 18.1 |

| Non capsulized hardener ※2 | 20phr | 24.5 | 31.0 | 35.4 | 56.3 |

| Grade |

Mean particle size [um] |

Capsule thickness |

Feature |

Viscosity [Pa・s] |

Gel time (Resin composition) [min] |

||

|---|---|---|---|---|---|---|---|

| 90℃ | 130℃ | 170℃ | |||||

| HX-3722 | 2 | Thin | Low temp,(80℃〜) and rapid cure | 100~500 | 11 | 1 | <1 |

| HX-3742 | 2 | Thick | Long pot life(with acid anhydride) | 200~600 | >30 | >30 | <1 |

| HX-3088 | 2 | Ex-thick | Long pot life(with acid anhydride) | 200~700 | >30 | >30 | >30 |

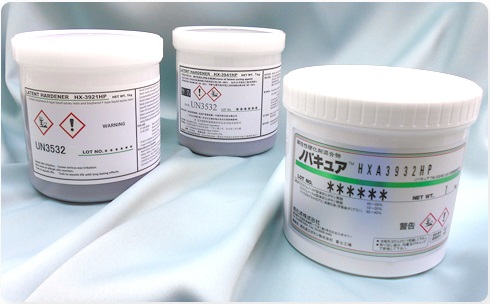

| HX-3921HP | 5 | Thin |

Low temp,rapid cure Low chlorine type |

50~130 | 11 | 1 | <1 |

| HX-3941HP | 5 | Thick |

Long pot life / solvent stable Low chlorine type |

50~250 | >30 | <1 | <1 |

| HXA3922HP | 2 | Thin |

Low temp,rapid cure Low chlorine type |

70~200 | 14 | 1 | <1 |

| HXA3932HP | 2 | Thick |

Long pot life / solvent stable Low chlorine type |

50~200 | >30 | 1 | <1 |

Products mentioned above are common grades.

please contact us if you have any requests regarding viscosity, curing start temperature, etc.

※Liquid BisA type epoxy resin(EEW:180g/eq):NOVACURE=100:30 (Recommended formulation ratio)